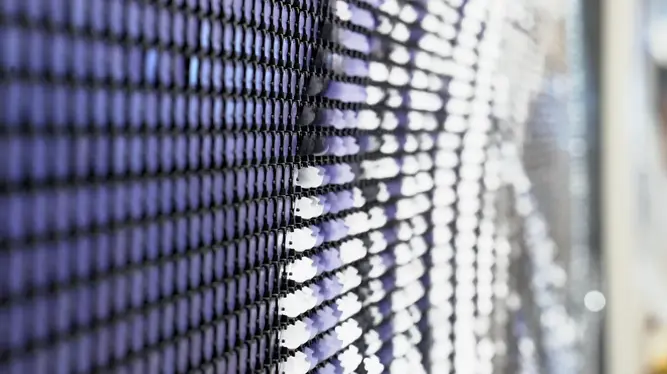

FLIP-DISC DISPLAY

AUGUST 2016 - OCTOBER 2021

BREAKFAST STUDIO

-

Design Engineering (Peripheral Components)

-

Production Management

-

Assembly Management

-

Project Management

-

Installation Drawings

-

Packaging Design

The Flip-Disc Display was developed by Breakfast in 2017. While the disc technology is decades old, the team modularized the concept into panels that could be installed in any desired size or configuration.

Paired with modern micro controllers and custom software, the physical discs could flip 30-60 fps, about 3-4 times faster than previous systems.

What truly makes the product stand out is the interactive element. Depth cameras installed near the display pick out individuals and project them in real time at a larger-than-life scale.

MY MANY ROLES

I was hired at Breakfast to contribute to the final stage of development of the original Flip-Disc system. My first roles were to assist with the quality control, develop assembly guidelines, and install the final product.

After assembling and installing hundreds of panels, we collected a long list of improvements we wanted to make to the original design. I worked alongside Breakfast's senior mechanical engineer to make the product more cost efficient, easier to assemble, and meet safety certifications.

During the growth of the product I also began directly managing the production, assembly, and installation of the product. I worked with domestic and international fabricators to resolve manufacturing issues and hired and trained our team of assembly technicians, all while juggling the development of our new products.

EVERY INSTALL UNIQUE

While the system was always designed to be modular, Breakfast's wide range of clients seemingly always posed new challenges. Whether the display needed to be installed in a tight space, placed on a curved wall, or suspended from the ceiling, there was a constant need need to design new brackets, housings, and mounting systems, all on tight deadlines.

In response to these constraints, I curated a selection of fabricators with fast turnaround times and utilized low-volume production methods that enabled us to get new designs in our hands as fast as possible.